Food processing

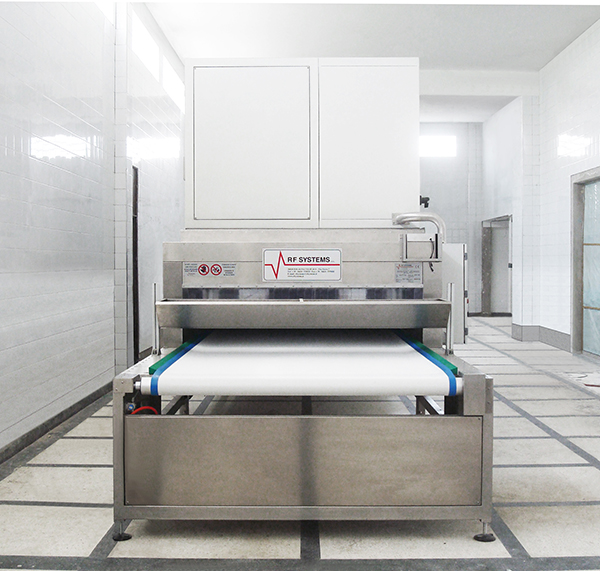

Radio Frequency industrial Defroster

Home » Radio Frequency food processing » Radio Frequency defrosters

Industrial Defroster

THERIO

THERIO is a RF equipment that ensures a rapid defrosting process, eliminating the need for large thawing rooms and minimizing the drip loss.

The process is uniform throughout the whole mass of the product, regardless of its size, weight and shape.

Benefits

Defrost in minutes any product cut and shape

Conventional defrosting systems (still air thawing, forced air/blast thawing, water sprinkling, water immersion systems, etc..) are slow and often generate product waste due to the poor process control.

Differently, RF defrosting is an endogenous and instantaneous method that delivers the product ready for the next step in a few minutes: the product to be defrosted, either in blocks or IQF, is placed on the conveyor belt of the RF machine and is submitted to rapid dielectric heating that brings its temperature just below the melting point of water, with no drip loss or bacterial deterioration.

In this way, other than saving time and preserving quality, last-minute orders can be easily managed and product waste is completely avoided.

Furthermore, being a continuous and in-line process, multiple handling is eliminated, with huge savings in labor cost.

Meat

- Beef

- Chicken, duck, turkey

- Pork

- Lamb

- Rabbit and hare

- Deer, hare, roe, reindeer, doe etc.

Fish and seafood

- Salmon and tuna

- Squid, calamari and octopus

- Pangasius, tilapia and halibut

- Mackerel and sardines

- Molluscs (scallops, mussels, etc.)

- Shrimps, prawns, lobsters, crawfishes, etc.

Vegetables and more

- Vegetables

- Legumes

- Fruit

- Juices and soups

- Liquid egg

- Butter and margarine

- Onion, garlic, potatoes etc.

Blocks and IQF

- Overlapped layers

- IQF

- Blocks up to 20 kg

- Chunks etc.

Loose or packaged

- Products in trays

- Carton boxes

- Plastic crates

- Plastic film

- Naked and loose products

Any shape and cut

- Muscles

- Neck

- Breast

- Kidneys

- Tongues

- Tenderloins

- Shanks etc.

Applications

Contact us for more information!

Our lab is equipped with pilot machines for product testing and demos. Book now a free test!